Welcome to Stam Flex –

Your Premier Expansion Joint

Manufacturer in Pakistan

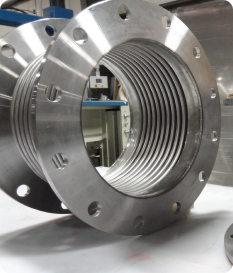

Imagine your industrial project running smoothly, without the worry of leaks, downtime, or unexpected maintenance. That’s the peace of mind you get with Stam Flex, the premier provider of high-quality expansion joints in Pakistan.

Stam Flex is the flagship brand of STAMECO Energy Solution Pvt Ltd, a company with a deep-rooted commitment to excellence, quality, and innovation. We don’t just sell expansion joints; we create solutions. Our team of experts works closely with you to understand your unique needs and design custom-made expansion joints that perfectly fit your application.

We have a broad line up of standard products to suit your project requirements. We stock a large variety (size and type) of bellows elements and fittings that can be swiftly put together to meet your needs in a timely manner. Having served in the industry for a long time, we enjoy the reputation of being the leading bellows expansion joint manufacturer and supplier.

Welcome to Stam Flex –

Your Premier Expansion Joint

Manufacturer in Pakistan

Imagine your industrial project running smoothly, without the worry of leaks, downtime, or unexpected maintenance. That’s the peace of mind you get with Stam Flex, the premier provider of high-quality expansion joints in Pakistan.

Stam Flex is the flagship brand of STAMECO Energy Solution Pvt Ltd, a company with a deep-rooted commitment to excellence, quality, and innovation. We don’t just sell expansion joints; we create solutions. Our team of experts works closely with you to understand your unique needs and design custom-made expansion joints that perfectly fit your application.

We have a broad line up of standard products to suit your project requirements. We stock a large variety (size and type) of bellows elements and fittings that can be swiftly put together to meet your needs in a timely manner. Having served in the industry for a long time, we enjoy the reputation of being the leading bellows expansion joint manufacturer and supplier.

Expansion Bellow Use: What are the benefits?

These are crucial components in many industrial systems, providing operational stability and longevity. The benefits include:

01

02

03

04

05

06

07

08

Expansion Joint: What Is It?

Expansion joints are used in piping systems to cushion vibrations and stress. They also have advantages, such as noise reduction and compensation for misalignment. Special expansion joints can also be constructed to accommodate thermal expansion in hot environments.

Metal expansion joints are commonly employed in applications that involve thermal expansion. If the temperature of the pipe rises, the metal expansion joint compresses to compensate for the movement and relieve tension on the pipe. Metallic bellows can be made from a range of materials, including stainless steel and nickel alloys.

So, the expansion joints hold parts together, absorb temperature-induced expansions and contractions, extend the structure’s service life, and reduce risk.

Excellence of Custom Solutions in Pakistan

Stam Flex is your reliable expansion joint supplier in Pakistan, serving industries such as petrochemicals, power generation, HVAC, and more. We pride ourselves on delivering products that perfectly meet the highest standards of quality and performance.

We understand that each project has different and unique demands. We take pride in our inclusive culture, where we enthusiastically welcome young talent and seamlessly integrate them into the culture of our company. Stam Flex is deeply committed to the growth and development of all our employees, whether they are seasoned professionals or young talents embarking on their career journey.

Diverse Configuration Options: Exploring the Variety

Stam Flex, a subsidiary of STAMECO Energy Solution Pvt Ltd, stands at the forefront of expansion joint manufacture in Pakistan, offering an impressive variety of configuration types. Our exhaust bellow use extends to industries including Oil and Gas, Aerospace, Power Generation, Petrochemical, Water, Wastewater, and more. Our commitment to versatility is evident by providing a wide array of configuration types to cater to the unique needs of various industries.

Stam Flex’s dedication to diversity underscores our commitment to excellence in serving the Pakistani market, all under the umbrella of STAMECO Energy Solution Pvt Ltd.

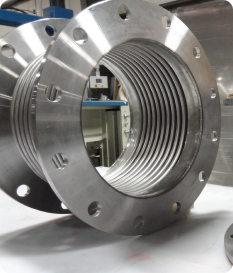

Expansion Joint Material Selection

Stam Flex creates metal expansion joints from a variety of materials. The application, physical qualities, and other properties, such as corrosion resistance and cyclic fatigue, influence the selection and use of particular metals and alloys.

Austenitic stainless steels of various grades are the most commonly used materials for our metal bellows. We have also supplied metal expansion joints in Inconel, Monel, Hastelloy, Other high Nickel alloys, Cobalt alloys, Titanium, Aluminium, brass, and other copper alloys, and many more specialized metal alloys.

Ready to experience the Stam Flex difference?

When it comes to expansion joint manufacturing in Pakistan, Stam Flex is the name you can trust. We commit to delivering exceptional products and services to meet your flexible needs.

Got technical questions? Need some advice? Our specialists are here to make your job easier. So, explore our products, or get in touch with our team today to discuss your expansion joints requirements.

Your satisfaction is our priority. Experience the Stam Flex advantage to get any assistance on technical issues and inquiries. Your project’s success starts here.

Frequently Asked Questions (FAQs)

- Increasing adaptability

- Decreased deflection forces

- Managing higher pressures and lowering thrust forces

- Extending the elasticity

- Spring rate reductions

Metal expansion joints are suitable for use in high-temperature situations. The maximum temperature that metal expansion joints can sustain varies by a number of factors, including the metal used, the design of the expansion joint, and the specific application requirements.

A metal expansion joint’s usual lifespan depends on several factors. Such as the metal used, the expansion joint design, the unique application, and the operating circumstances. However, a well-designed and well-constructed metal expansion joint can last for many years in general. Therefore, our expansion joints are manufactured to serve the purpose of longer lifespans.

Metal expansion joints are suitable for use in corrosive environments depending on a number of parameters. Also, it is better to check such things as the metal used, the expansion joint design, and the kind and concentration of the corrosive substance.